The Netra VS6 from Accura Pharmaquip is an

Automatic Tablet Inspection Machine, Capsule Inspection Machine

The Netra VS6 from Accura Pharmaquip is a cutting-edge technological innovation that allows hands-free, high-speed tablet inspection, defect sorting and reporting that improves productivity and finished goods quality. It brings mechanical, electronic, image capturing and processing, and computing technologies in a compact and seamless solution.

Eye inspection Versus Netra VS6

Catch manufacturing defects that even the most experienced and sharpest of eyes cannot pick up, and at a speed that a human brain cannot process. No wonder it is called Netra, a Sanskrit word for the eye - to guide, conduct, and miss nothing.

- Highly accurate inspection

- Inspection output : 100000 - 150000 per hour

- Lowest false rejection in its segment

- Robust built quality

- Detailed inspection report with rejection pie chart

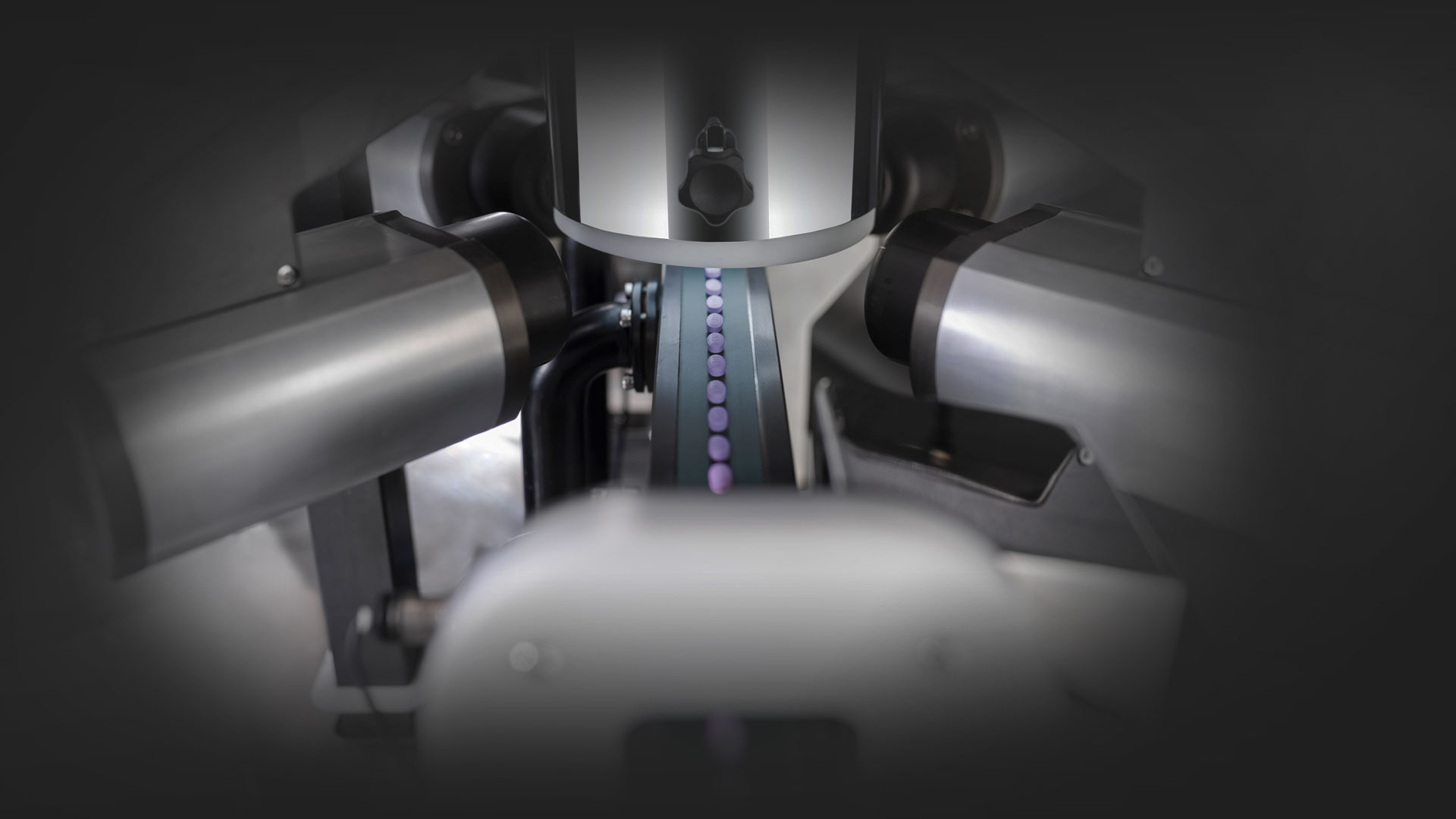

DEFFECTS INSPECTED :

* Shape * Size Cracks * Chipping * Black Spots

* Dirt * Dents * Rough Surface * Colour Variations

Inspect every 100 micron of every tablet

Self-diagnostic tools for maintenance

Analyze 8 defects of every tablet in milliseconds

Force Multiplier for Pharma manufacturing

360 DEGREE INSPECTION :

Netra VS6's global acceptance and demand in mature markets is a clear statement of superior value. The top-of-the-line customers are delighted with the ROI that is immediately perceptible with a measurable jump in efficiency and defect-control.

6 camera vision system | Product subjected to 360 degree inspection | Every 50 microns of every product is analysed |

Quickest changeover in its segment | Compact design, easy to use & maintain

Brought to you by

Accura Pharmaquip manufactures sophisticated engineering products from a fully equipped, enclosed factory in an industrial area close to the international shipping port near Mumbai. Global companies in world locations import and trust Accura machines at every level of operations. The latest from the Accura stable are research, development and commercial production of sophisticated technology marvels like automated Induction Seal Inspection and Tablet inspection machines successfully deployed in large pharmaceutical companies in India and around the world.

Overview

Catch manufacturing defects that even the most experienced and sharpest of eyes cannot pick up, and at a speed that a human brain cannot process. Add to it the end-to-end efficiency, repeated application of learning on new batches, analyses, a seamless coupling for your manufacturing process - and you have a huge force multiplier in your hands. The generated reports that capture the results and attributes contribute to valuable learnings and course setting - an objective and analytical advantage of Netra VS6 over conventional eye inspection. No wonder it is called Netra, a Sanskrit word for the eye - to guide, conduct, and miss nothing.

Flaws in tablets inspected

Features

Netra VS6 is FDA ‘21 CFR part 11’ \compliant.

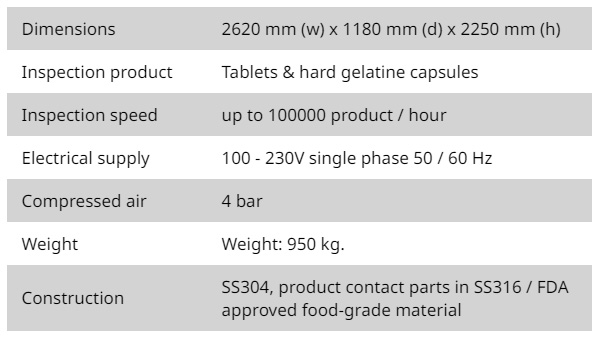

The 6-camera vision system

6 industrial vision cameras inspect every 100 micron of every tablet, compositing a 360 degree view in milliseconds. A few salient features define the Netra VS6 vision system

- Servo motors that help the precise adjustments of camera focal length.

- Well-managed cabling and internal fastenings to maintain connection integrity.

- Inbuilt, high intensity light source for optimal illumination of the inspection zone, for the cameras.

- The high-resolution depth of each camera sensor and the computing electronic brain handling the image data feed, constitutes a high-speed intelligent system more efficient than human intervention.

High Speed tablet inspection

The use of high speed image capture and image processing technology allows Netra VS6 to evaluate each 100 micron of each tablet for up to 8 defects, at an astonishing speed of around 1,00,000 tablets /hour (depending on product size).

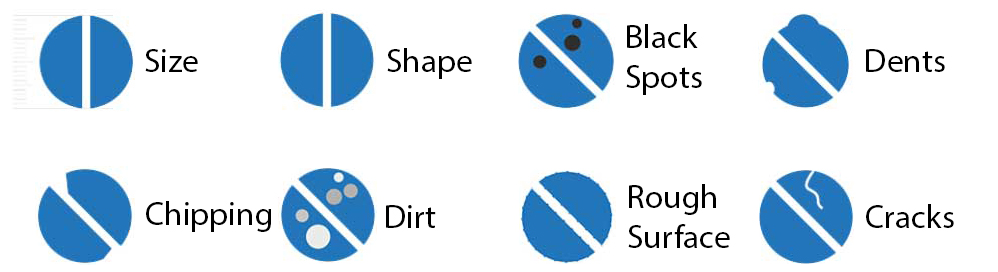

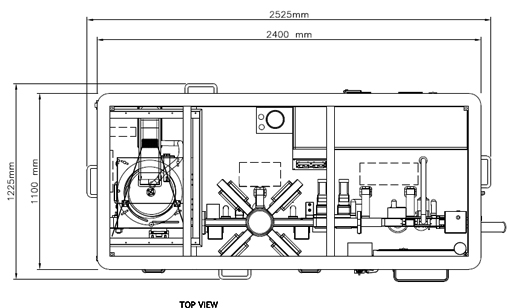

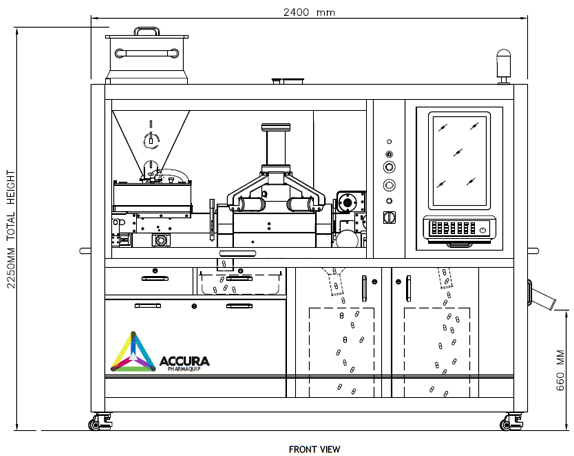

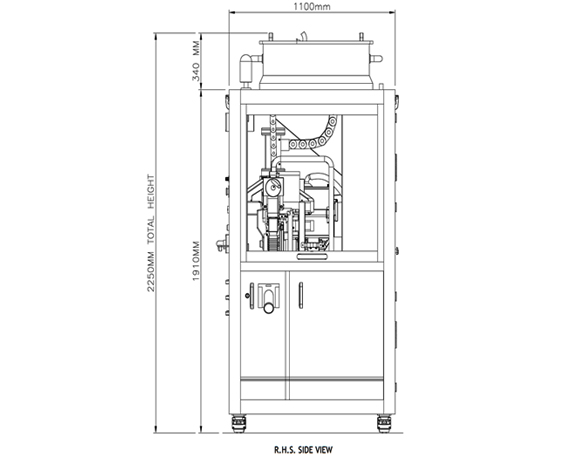

Build

Netra VS6 is built to conform to global regulations in pharmaceutical industry, and last long. The body and all the non-contact parts are made of S.S.304 (heat-resistant, corrosion-resistant, and suitable to industrial environments), with product contact parts in S.S.316 / FDA approved food-grade material. Dimensions: 2620 mm (w) x 1180 mm (d) x 2250 mm (h). Weight: 950 kg.

Vibratory Tray & Rotary Feeder

Netra VS6 is built to conform to global regulations in pharmaceutical industry, and last long. The body and all the non-contact parts are made of S.S.304 (heat-resistant, corrosion-resistant, and suitable to industrial environments), with product contact parts in S.S.316 / FDA approved food-grade material. Dimensions: 2620 mm (w) x 1180 mm (d) x 2250 mm (h). Weight: 950 kg..

Conveyors

Conveyors I and II are designed with an internal vacuum underlay, which holds the product in place. They are Servo-operated for movement precision of the product along the inspection zone. The second conveyor is built for automatic, intelligent height-adjustments according to the thickness of the product. Human intervention is thereby rendered redundant.

Rejection mechanisms

The rejection ports are located along the inspection conveyors and operate pneumatically with compressed air pressure. The rejected material travels down chutes to a collection bin.

Change Parts

The change part is a product-specific requirement. The selection depends on the width or the diameter of the product. It is exceedingly simple to replace – without the use of any tools, simply by loosening and tightening of four knobs by hand.

Reporting

Automatic and minute reporting increases integrity and efficiency of operation for pharmaceutical industry and it is a vital feature of Netra VS6. The record of every run is maintained by four types of reports -- Batch Inspection, Audit Trail, Alarm, Parameter Setting, and Batch Trend. All these reports are indelible to prevent tampering or suppression of any event information.

The Batch Inspection report is the most significant, wherein the data carries a permanent record of the product name, product code, batch number, user ID, batch quantity, and the name of the personnel who prints out the report of the completed batch. Respective records of passed / failed product by each camera, and a record of the total batch are obtained. Pie charts featuring each defect displayed for every rejected product, are shown.

The Audit Trail report makes a record of every event, date, time, and stamping of each batch. The Alarm report keeps data of every alarm in a run, if any. The Parameter Setting report maintains records of all the parameters set before a run. And the Batch Trend report presents saved information of the likelihood of a defect occurring by which the product tends to get rejected.

Build

Netra VS6 is built to conform to global regulations in pharmaceutical industry, and last long. The body and all the non-contact parts are made of S.S.304 (heat-resistant, corrosion-resistant, and suitable to industrial environments), with product contact parts in S.S.316 / FDA approved food-grade material. Dimensions: 2620 mm (w) x 1180 mm (d) x 2250 mm (h). Weight: 950 kg.

Specifications

Layout

Operations

As the product moves through Conveyor 1, each tablet is inspected by five cameras (C1-C5) placed precisely to capture its image from the top (C1) and from four lateral angles (C2-C5). Any tablet that fails this inspection is pneumatically discarded through the first rejection point (R1) into an internally provided rejection bin.

The filtered tablet stream now travels along Conveyor 2, where the vacuum-pull reverses, and the underside of the tablet is inspected by the bottom camera (C6). Any defective product at this stage is rejected through the second rejection point (R2) into the internally provided rejection bin.

The flawless product stream is collected in a separate bin at the discharge end of the machine.

Maintenance & Troubleshooting

Your Netra VS6 has inbuilt self-diagnostic modes for periodic maintenance and a special screen for hardware testing. In addition, each component has overrides for full manual testing. Software driven simplified troubleshooting is a step-by-step process with clear on-screen instructions. Every situation that could possibly arise and would be in the user’s scope to set right, is covered.

The Netra VS6 Tablet Inspection machine from Accura Pharmaquip is a cutting-edge technological innovation that allows hands-free, high-speed tablet inspection, defect sorting and reporting that improves productivity and finished goods quality. The video demonstrates the workflow of Netra VS6.

About Us

The journey of manufacturing to precision engineering

Accura Pharamaquip is a family-owned boutique engineering company, based in Mumbai, India. It started as an intrapreneurial venture, its inception founded upon decades of experience in making engineering parts and accessories for the pharmaceutical industry.

Like all family enterprises, roots and cultural solidity set the foundation for every initiative and allowed freedom of decisions. It’s an evolutionary experiment that has worked. Manufacturing of parts and accessories has led to creation of beautiful, state of the art, precision engineered machines that the world recognizes and values.

The leadership remains grounded and passionate about innovative technology and drives the company with the Kaizen principle of daily continuous improvements. It’s okay to try and fail. It’s not okay to remain static. There is no finish line.

NILESH PHADNIS

Founder, Director

PRAKASH PHADNIS

Co-Founder, Director

MAHESH PHADNIS

Director

ADITI PHADNIS

DirectorTEAM NETRA

Netra is a labour of love and a result of dedicated work of many years by an exceptional team of engineers and managers, indoctrinated with the intrapreneurial vision of Accura Pharmaquip.

VIKAS MORE

VIJAY KAMBLE

SANDEEP MADIWALA

Till the end of the last century, the parent company was fabricating general-use equipment. But the new leadership stepped in with a vision to create beautiful, state of the art, precision engineered machines at global standards. Accura Pharmaquip now manufactures sophisticated engineering products from a fully equipped, enclosed factory in an industrial area close to the international shipping port near Mumbai.

The first export project undertaken was for Oman. Projects in the Middle East, US and Europe followed with very significant contributions to the rapidly modernizing and exploding Indian Pharmaceutical Industry. Today, global companies in world locations import and trust Accura machines at every level of operations. The latest from the Accura stable are research, development and commercial production of sophisticated technology marvels like automated Induction Seal Inspection and Tablet inspection machines. The quest for excellence continues unabated.

Enquiry Form

* Indicates Compulsory Fields